what is a composite material?

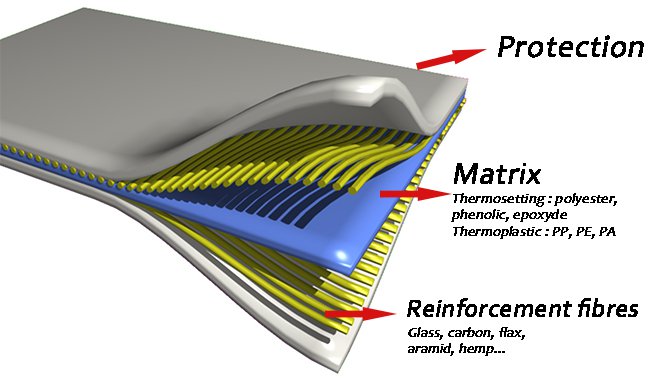

A composite material can be defined as a combination of a matrix and a reinforcement, which when combined gives properties superior to the properties of the individual components.

The reinforcement fibres can be cut, aligned, placed in different ways to affect the properties of the resulting composite.

The matrix, normally a form of resin, keeps the reinforcement in the desired orientation. It protects the reinforcement from chemical and environmental attack, and it bonds the reinforcement so that applied loads can be effectively transferred.

There are two different types of composite materials:

• “Large diffusion” composite materials: their mechanical properties are weaker but their cost is suitable for mass production.

• “High performance" composite materials which have high specific mechanical properties and a high unit cost. This type of composite material is often used in aeronautics and space.

Nowadays, there is a large range of composite materials that are generally classified into three families according to the type of matrix:

– Organic matrix composites (OMCs), which make up the largest volumes by far on an industrial scale today;

– Ceramic matrix composites (CMC), which are reserved for very high-tech applications at high temperatures such as space, nuclear and military, as well as brakes (carbon brakes);

– Metal matrix composites (MMC).

The main advantage of composite materials is that they can be custom designed. This means that highly anisotropic materials can be designed. This advantage is used when designing the part, and takes into account the mechanical stresses it will undergo. The other advantage of composite materials is that they have a very low density, which is used to make aeronautic and spatial structures lighter.